Pump casings serve to seal off the intside of the pump to atmosphere to prevent leakage and retain pressure. In the case of centrifugal pumps they surround the pump rotor which transmits energy to the fluid handled via the impellers mounted on the rotating shaft.

In the case of positive displacement pumps, they surround the rotary or reciprocating displacement elements (e.g. one or more pistons).

The inlet and outlet nozzles serve to direct the fluid handled into and out of the pump and are often classified by their function as inlet or suction nozzle and discharge nozzle. They are either attached to the piping.(e.g. using flanges, pipe fittings), or: The suction side nozzle is immersed in the open liquid tank, i.e. vertical casing pumps.

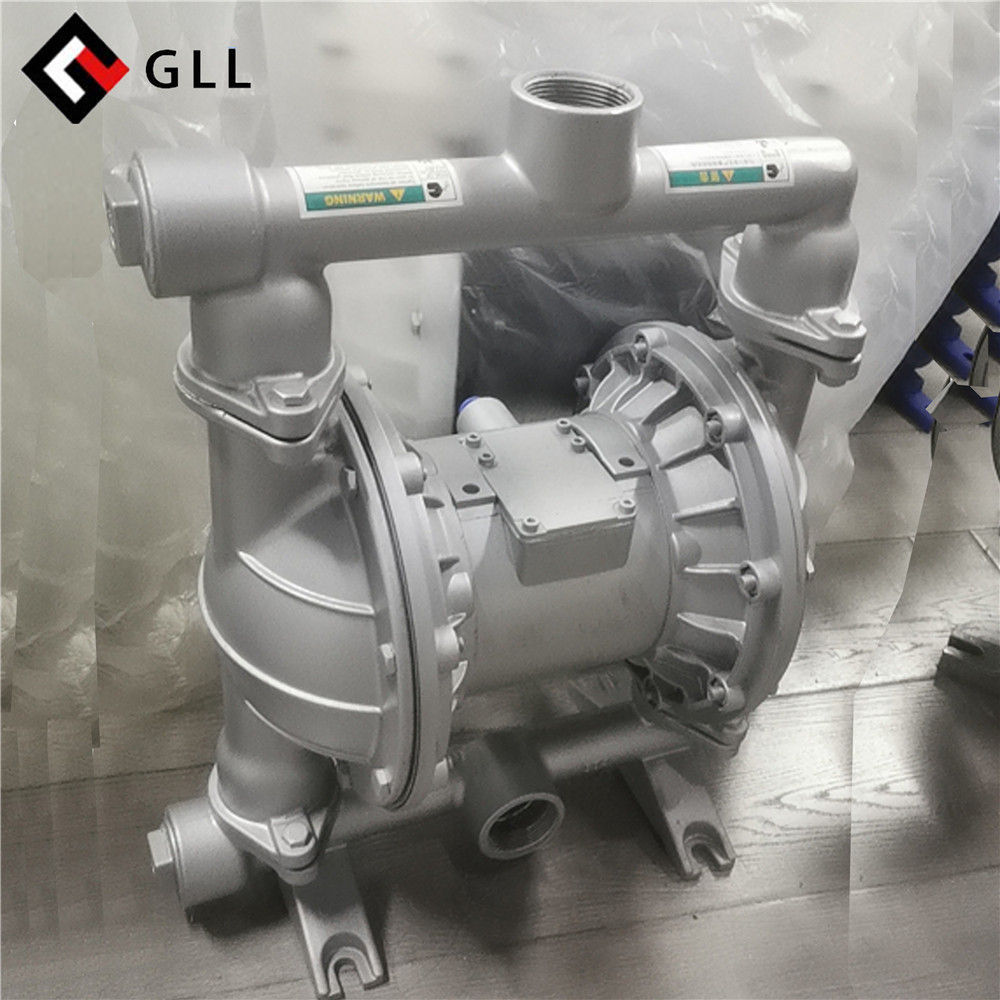

Pump casings are a vital component in liquid delivery systems. They are widely used in various types of mechanical equipment, from water pumps to chemical pumps to pumps in the oil and gas industry.

We use advanced aluminum alloy casting technology and a variety of casting methods to ensure product quality and precision. The casting process of the pump housing usually involves the following key steps:

Material selection: To ensure better strength, corrosion resistance, and thermal conductivity, we utilize high-quality aluminum alloy materials that undergo rigorous screening.

Casting Techniques and Mold Design: Tailored to the requirements of diverse pump casings, we utilize various casting methods such as gravity casting, sand casting, and low-pressure casting. The pump casing achieves precise dimensional accuracy, a smooth surface finish, and robust structural integrity through various methods, each providing unique advantages.

After casting, the aluminum alloy pump casing undergoes heat treatment to boost its strength and hardness.

Our aluminum alloy pump housing offers several key advantages. Its outstanding corrosion resistance ensures long-term stability, even in harsh environments like seawater, chemical media, and high humidity. The lightweight design of the aluminum alloy reduces the pump system’s overall weight, making handling and installation more convenient. Moreover, the material’s high strength and temperature resistance enable it to endure substantial mechanical loads and function efficiently across various temperature ranges. Furthermore, GLL utilizes environmentally friendly materials and processes that minimize harmful emissions during casting, while the recyclability of aluminum alloy aligns with modern industrial sustainability goals.