Product Description

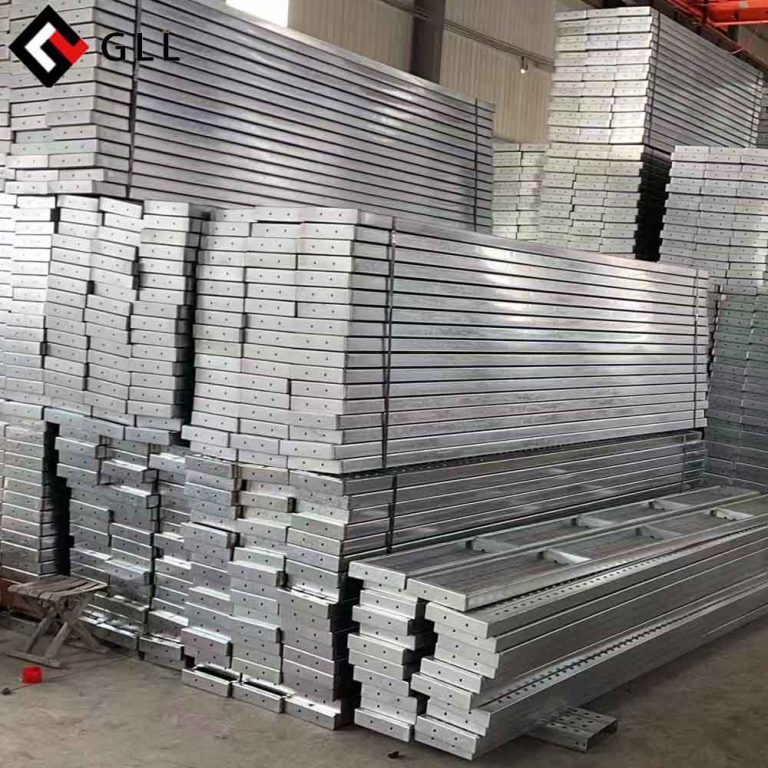

Our GLL Galvanized Scaffolding Boards Walking Platform is designed for durability, safety, and efficiency in heavy-duty construction applications. Manufactured using high-quality galvanized steel, these platforms are resistant to rust and corrosion, providing long-lasting service even in the harshest environments.

Key Features:

Galvanized Steel Construction:

Heavy-Duty Load Capacity:

Anti-Slip Surface:

Easy to Install and Secure:

Durable and Long-Lasting:

Versatile Application:

Compliant with Safety Standards:

Detailed photos

Packaging and shipping

1. Carton Box Packing: Cost-effective and allows for higher loading capacity, though it may pose challenges for loading and unloading.

2. Wooden or Steel Pallets Packing: Easy loading and unloading.

3. Customized Packing: Options selected based on clients’ requirements

4. Shipping: Better to choose sea shipment, if urgent demand can choose Air shipment

Company Profile

GLL is a leading manufacturer in China, offering comprehensive one-stop solutions that encompass die casting, gravity casting, sand casting, investment casting, CNC machining, surface treatment, and assembly. As a professional OEM/ODM company, we combine extensive production expertise with the ability to design or recommend products tailored to meet our customers’ unique needs. Our global customer base spans North America, Europe, South America, Asia, Oceania, and Africa, reflecting our commitment to serving diverse markets worldwide.

Specialization and Product Categories

GLL specializes in manufacturing high-quality die-cast parts for a broad range of industries, with a strong emphasis on OEM and ODM solutions. Our product offerings include:

Our advantage

As an extension of our manufacturing groups, our foundry is dedicated to understanding our customers’ businesses and developing the necessary capabilities to meet their needs for commodities we support.

Copyright © 2023·GLL CASTINGAll rights reserved.