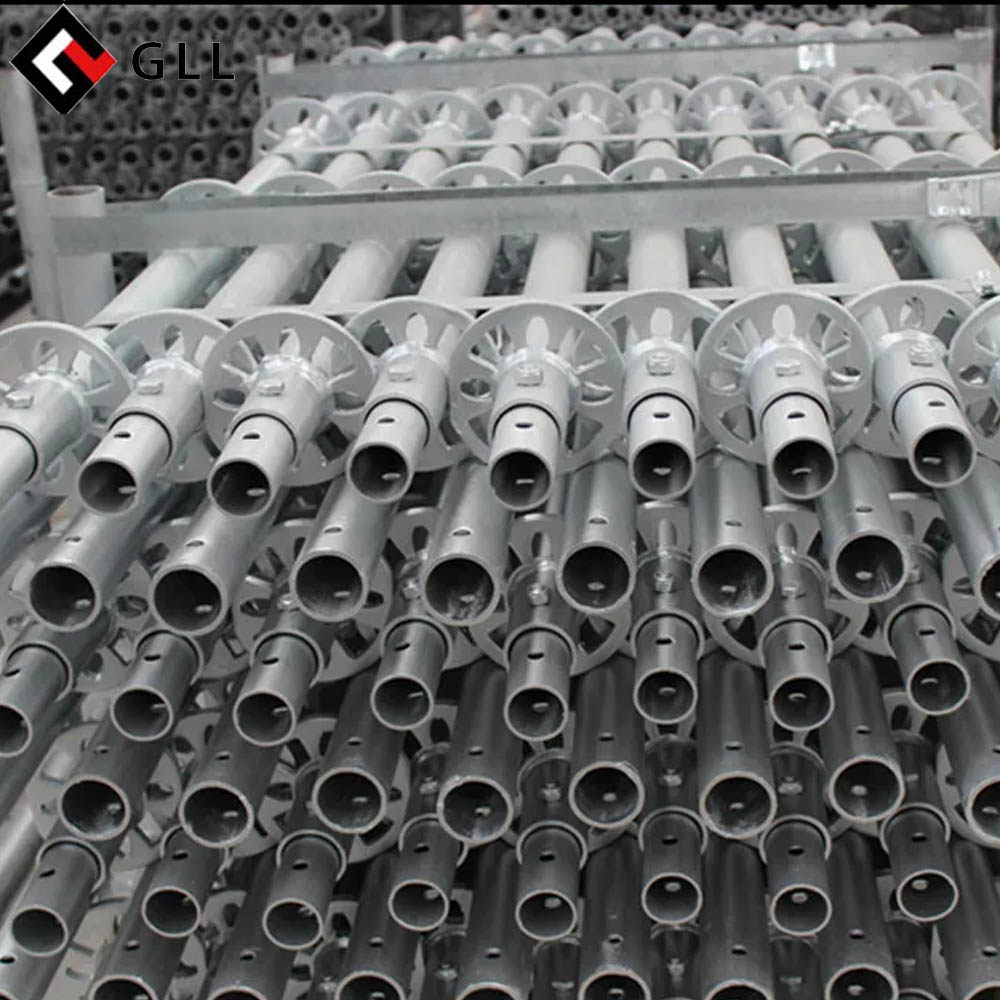

Product Description

GLL Ring Lock Scaffolding Couplers are high-strength and durable connectors designed for various construction and engineering projects, ensuring the stability and safety of scaffolding systems.

Product Features

High-Strength Aluminum Alloy / Carbon Steel – Made from premium aluminum casting or forged carbon steel, offering excellent tensile strength and corrosion resistance for various working environments.

Precision Manufacturing – Produced with advanced casting or stamping technology, ensuring accurate dimensions and secure connections for enhanced scaffolding stability.

Strong Compatibility – Designed to fit standard Ring Lock scaffolding systems, seamlessly connecting with vertical standards, ledgers, and diagonal braces for quick assembly and dismantling.

Reliable & Safe – High load-bearing capacity, compliant with international scaffolding safety standards (e.g., EN, ANSI, ISO), making it suitable for construction, bridgework, and shipbuilding industries.

Anti-Rust Coating – Galvanized or powder-coated surface treatment to prevent rust and extend service life, suitable for harsh environments.

Specifications

Material: Aluminum Alloy / Carbon Steel

Surface Treatment: Hot-Dip Galvanized / Electro-Galvanized / Powder-Coated

Tube Compatibility: 48.3mm / 60.3mm (Customizable)

Load Capacity: Compliant with international scaffolding safety standards

| Item | Description |

|---|---|

| Single Coupler | A fitting used to connect two scaffold tubes in a straight line, typically used for linear connections. |

| Double Coupler | A fitting used to connect two scaffold tubes at a right angle, ensuring structural stability. |

| Swivel Coupler | A coupling that allows adjustable angles, providing flexibility in connecting scaffold tubes in different directions. |

| Scaffold Tube | A steel tube that complies with BS1139/EN74 standards, typically with a 48.3mm external diameter, used as the primary support element in scaffolding systems. |

| Board Support | A fitting used to support scaffold boards, ensuring the stability of working platforms. Typically used in conjunction with support brackets. |

| Safety Net | A protective net installed on scaffolding to shield workers from falling debris or other hazards. |

| Base Plate | A component placed at the base of the scaffold to provide stability and distribute the load evenly on the ground. |

| Ledger End | A fitting used to connect horizontal ledgers (beams) to the scaffold system, ensuring the overall stability of the structure. |

| Cross Brace | A brace used to strengthen the scaffold structure, preventing lateral or longitudinal displacement. |

| Clamps | Fittings used to connect and secure scaffold tubes together, including single and double couplers, to ensure strong and stable connections. |

Detailed photos

Packaging and shipping

1. Carton Box Packing: Cost-effective and allows for higher loading capacity, though it may pose challenges for loading and unloading.

2. Wooden or Steel Pallets Packing: Easy loading and unloading.

3. Customized Packing: Options selected based on clients’ requirements

4. Shipping: Better to choose sea shipment, if urgent demand can choose Air shipment

Company Profile

GLL is a leading manufacturer in China, offering comprehensive one-stop solutions that encompass die casting, gravity casting, sand casting, investment casting, CNC machining, surface treatment, and assembly. As a professional OEM/ODM company, we combine extensive production expertise with the ability to design or recommend products tailored to meet our customers’ unique needs. Our global customer base spans North America, Europe, South America, Asia, Oceania, and Africa, reflecting our commitment to serving diverse markets worldwide.

Specialization and Product Categories

GLL specializes in manufacturing high-quality die-cast parts for a broad range of industries, with a strong emphasis on OEM and ODM solutions. Our product offerings include:

Our advantage

As an extension of our manufacturing groups, our foundry is dedicated to understanding our customers’ businesses and developing the necessary capabilities to meet their needs for commodities we support.

Copyright © 2023·GLL CASTINGAll rights reserved.