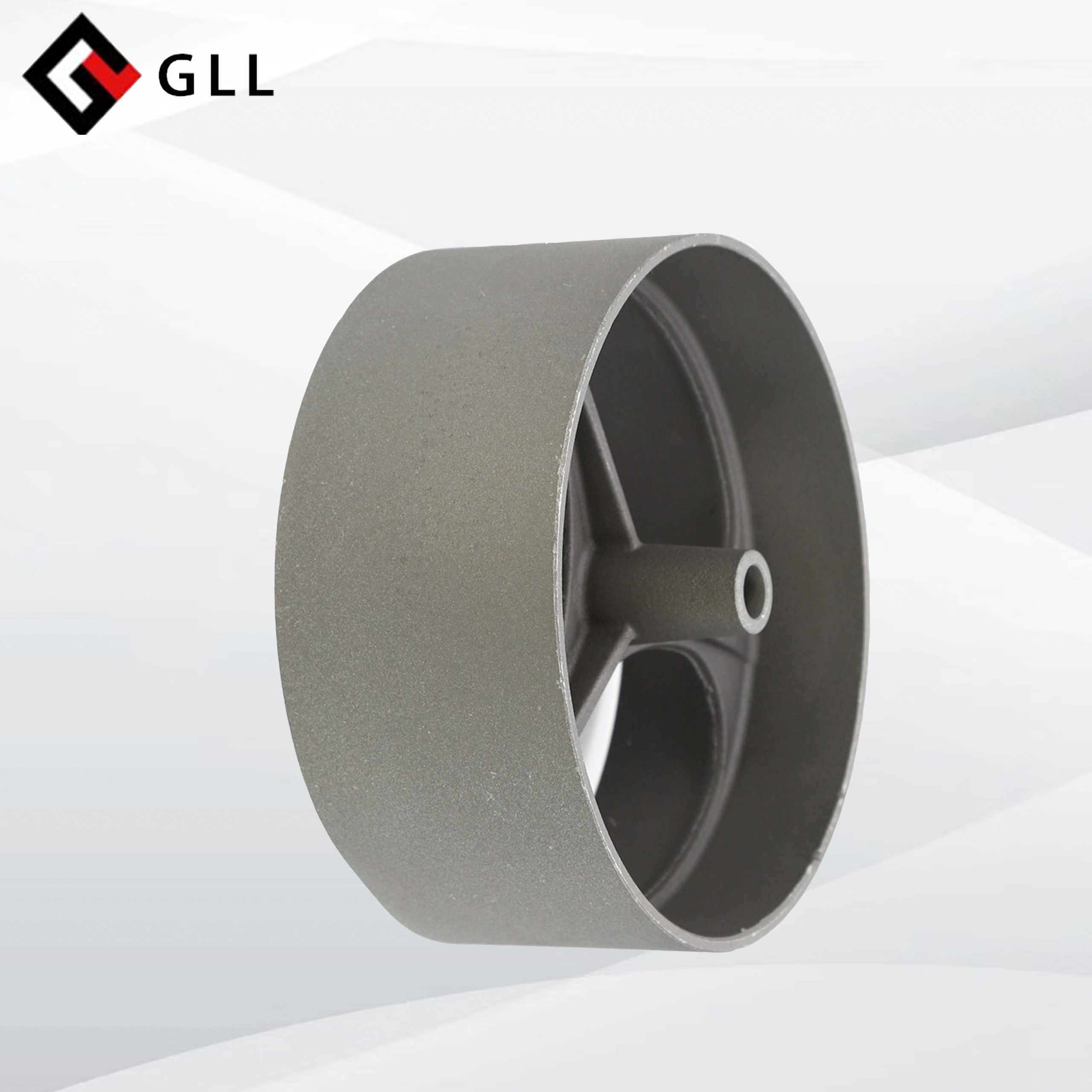

Ideal wheel hub materials usually need to have strength, durability, lightweight characteristics, and corrosion resistance. Common wheel hub materials include steel, aluminum alloy, and carbon fiber. Among these materials, aluminum alloy is generally considered the best choice because of its excellent strength-to-weight ratio, good corrosion resistance, and ability to effectively absorb impact, which enables aluminum alloy to provide both excellent performance and safety in automotive applications.

Determine your fitment and tire size. Be sure to consider suspension type, ride height, driving conditions, tire size, alignment, and fender modifications. We highly recommend researching other owners’ fitment setups. This will be the best way to get an idea of what setup you need based on the type of stance you wish to achieve.

The Forged One-Piece Forged Wheel is a two-piece, quick-assemble addition to the GLL Series wheel family. The two-piece wheels are machined from only the highest quality forged 6061-T6 aluminum, creating a wheel that is not only strong but stiff and lightweight. All wheels are designed and machined with optimal performance in mind, not only reducing overall weight but also maintaining overall strength. GLL Forged wheels are available in a variety of powder coat finishes. All wheels meet the highest quality standards for finish. Dual JWL and VIA certified.

We utilize cutting-edge aluminum alloy casting technology, paired with advanced precision machining equipment, to ensure that each wheel hub meets the highest benchmarks for strength, aesthetics, and durability. The core production processes encompass:

The high-purity aluminum alloy is first melted in an advanced smelting furnace, where it is carefully liquefied. The molten aluminum is then precisely poured into molds through advanced methods like low-pressure casting and gravity casting. This detailed process ensures that the wheel hub maintains optimal strength and uniformity in its structure.

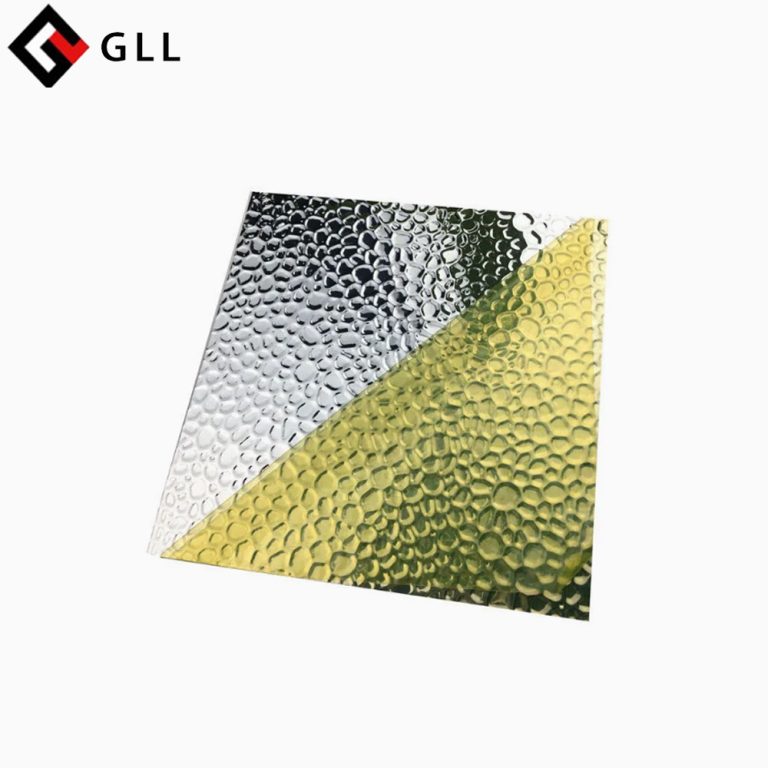

Once formed, the aluminum alloy wheel hub is precision-machined using CNC machines to achieve accurate dimensions and a smooth surface. To improve durability, corrosion resistance, and visual appeal, surface treatments such as electroplating, spraying, and anodizing are applied. These treatments also provide customers with a range of color choices, allowing for personalized customization.