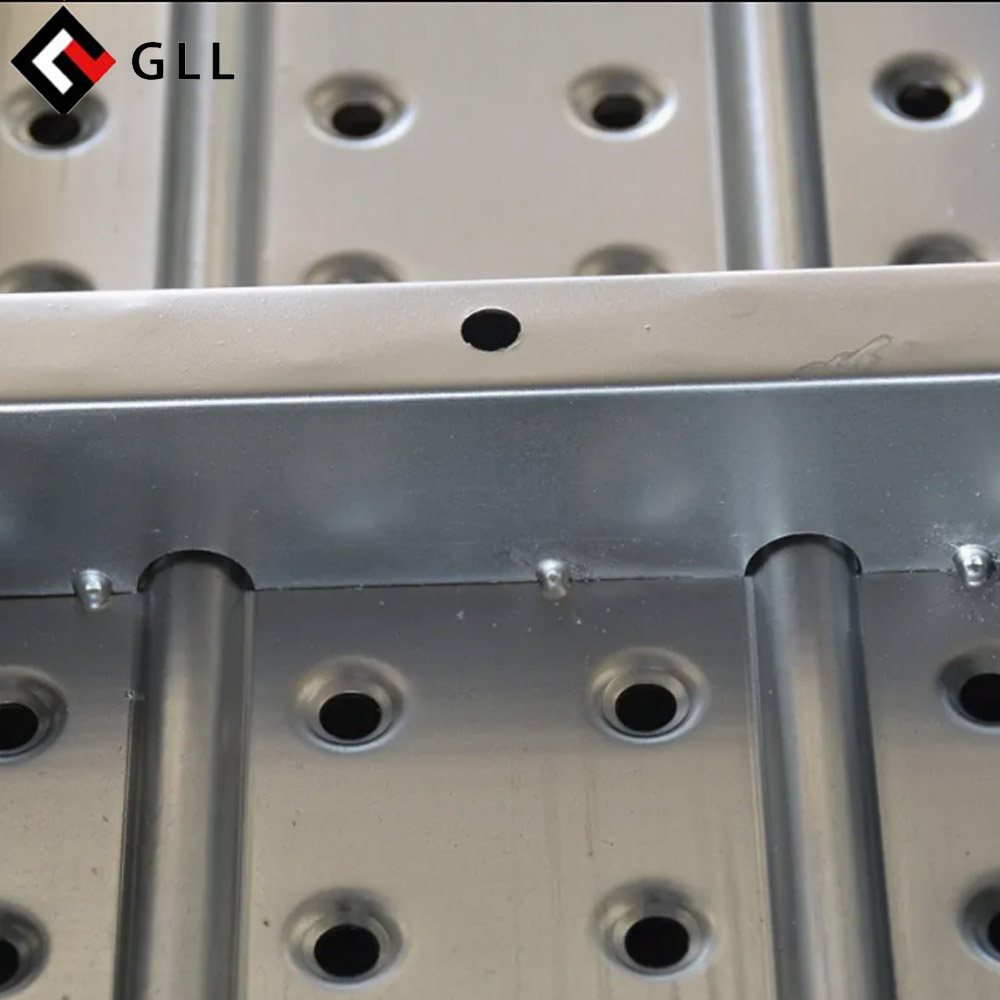

GLL galvanized inner angle plate uses high-quality low-carbon steel plate as the base material, and the surface is covered with a uniform and dense zinc layer. This process gives the product three core advantages:

Excellent corrosion resistance:

GLL unique zinc layer forms a physical barrier in harsh environments such as humidity, acid and alkali, effectively isolating oxygen and moisture, and preventing steel from oxidizing and rusting. High strength and impact resistance.

GLL galvanizing process enhances the mechanical properties of steel. which can withstand mechanical collisions and long-term load pressure during construction, reducing the risk of deformation.

Fireproof and heat-resistant: The galvanized layer forms a zinc oxide protective film at high temperatures, which slows down the spread of flames. After testing, our GLL galvanized inner angle plate has no discoloration or deformation at 310℃ for 120 hours, which meets the requirements of building fire protection GLL Galvanized Internal Corner Board achieves a double breakthrough in product performance and construction efficiency through technological innovation

Precision forming process: Adopting cold bending forming technology, the product has a right angle accuracy of ±0.5mm and no burrs on the edges. It can be directly used for the edge closing of corners, columns and other parts, reducing the need for secondary processing.

Balance between environmental protection and economy: The galvanizing process is a chromium-free environmentally friendly treatment that complies with RoHS standards; at the same time, the product has a service life of more than 20 years, low maintenance costs, and significant advantages in life cycle cost (LCC).

Our GLL galvanized inner corner plates are widely used in multiple stages of construction projects:

Structural protection: As protective strips for wall corners, door and window openings, they can resist damage during construction.Used in wet areas such as basements and bathrooms to prevent concrete from alkali corrosion.

Decorative edge trimming: Replaces traditional wooden or plastic corner guards to improve the durability and aesthetics of public buildings such as commercial complexes and hospitals. Seamlessly connected with gypsum board and metal ceiling systems to create a simple and modern design style.