Aluminum die casting is a popular manufacturing process used to produce complex and intricate parts with high precision and consistency.

The Aluminum die casting process involves injecting molten aluminum into a mold cavity under high pressure, which solidifies and forms the desired shape. The resulting products are lightweight, durable, and have excellent mechanical properties, making them ideal for a wide range of applications.

The below are some of the most common applications of aluminum die casting:

- Aerospace Parts: Aluminum die casting is also used in the aerospace industry to produce parts such as engine components, aircraft structures, and landing gear. These parts need to be lightweight, strong, and able to withstand extreme temperatures and pressures.

- Automotive Parts: Aluminum die casting is widely used in the automotive industry to produce lightweight and high-performance parts such as engine blocks, transmission housings, and suspension components. These parts are resistant to corrosion and have excellent strength-to-weight ratios, making them ideal for use in vehicles.

- Electronics: Aluminum die casting is used to produce a wide range of electronic components, including computer parts, mobile phone cases, and audio equipment. These parts are lightweight, durable, and able to dissipate heat quickly, making them ideal for use in electronic devices.

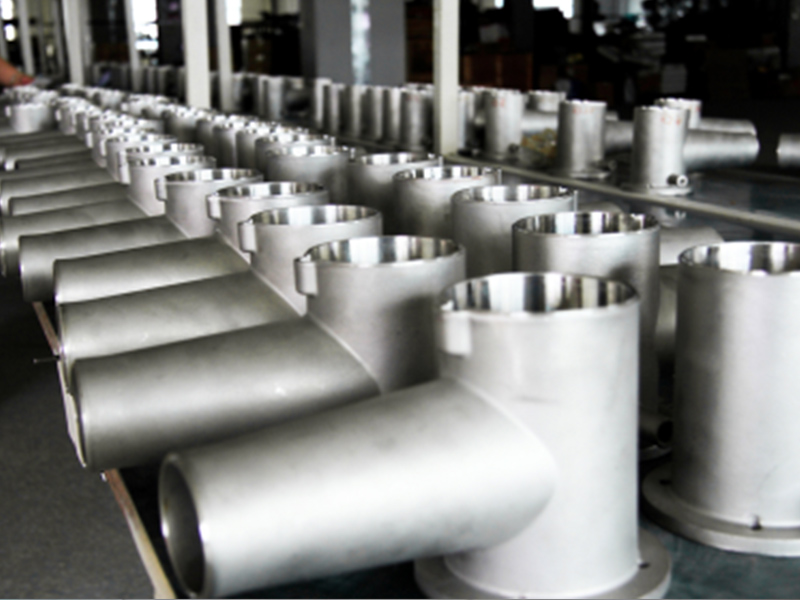

- Industrial Equipment: Aluminum die casting is used to produce a wide range of industrial equipment, including pumps, valves, and machinery components. These parts need to be strong, durable, and able to withstand harsh environments.

- Lighting: Aluminum die casting is commonly used to produce lighting fixtures such as streetlights, outdoor lighting, and indoor lighting. These fixtures need to be durable, weather-resistant, and able to dissipate heat quickly.

Aluminum die casting is a versatile and widely used manufacturing process that can produce complex and intricate parts with high precision and consistency. Its lightweight, durable, and excellent mechanical properties make it ideal for a wide range of applications, including automotive, aerospace, electronics, lighting, and industrial equipment. Gll casting offers the professional OEM and ODM service, any demand, kindly contact Gll casting freely.